Company Insight

Sponsored by Rail Technology International

Autonomous Systems and Smart Technologies is the Key to Creating a Better Future

Rail Technology International (RTI) was first labelled as "innovators" within the rail industry in 1988, developing never before seen technologies for a very traditional space. Since then, the company has designed and developed world-leading technologies, bettering rail flaw detection across the world, ultimately setting a higher standard for best practices and redefining how the rail industry operates.

RTIdesign, develop and distribute agile vehicles, using smart technologies.

Aerial view of the derailment. Image: UK Government

Why Plan Safe?

With over a decade of experience in the development of complex and high-risk infrastructure, we bring together extensive project, communication and safety methodology to deliver safe rail operations to workers and users.

Our Plan Safe consultants have delivered safety assurance programs for some of Australia’s most recent rail projects – including the Waratah ETCS upgrade in Sydney CBD - and offer a profound understanding of the needs and complexities inherent in the design, build and implementation of transport infrastructure.

We will work closely with your team, stakeholders, Independent Safety Assessors, clients, government bodies, unions and regulators to meet the assurance, accreditation, risk and training requirements of all parties.

Speed and Efficiency

GHH-BONATRANS designs, manufactures and supplies complete noise absorbing systems specifically aimed for different market segments of rail passenger transportation (urban, suburban and inter-city).

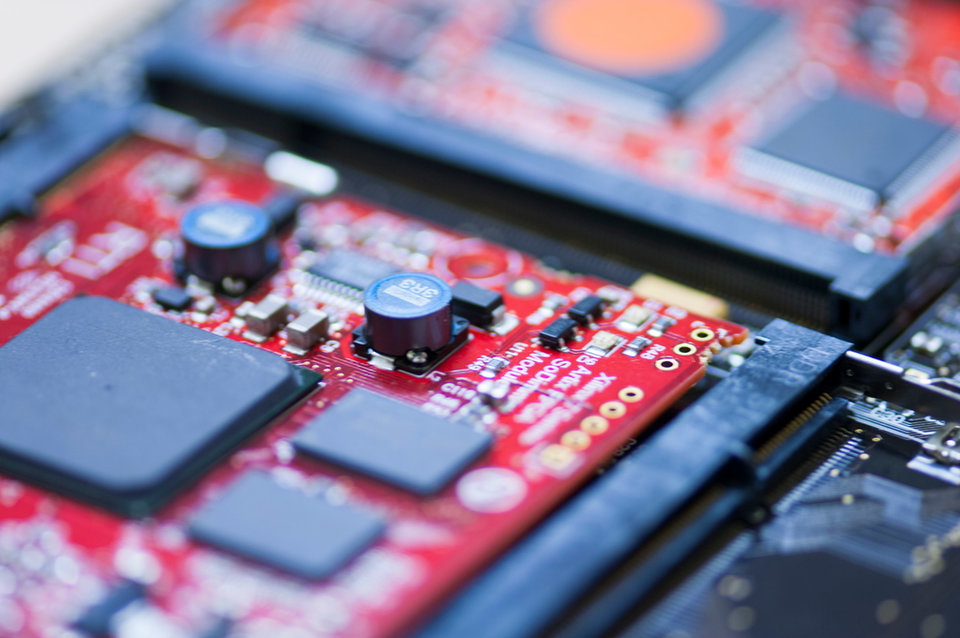

By introducing machines that employ Artificial Intelligence (A.I), decisions are made about rail surfaces and internal flaws in a faster and more detailed way. It’s often seen within the industry that analysis can be very timely, and naturally, human findings can result in slight errors. By using A.I there is no subjectivity in the decision making process; rail surfaces and internal flaws can be analysed more efficiently, providing consistency and repeatability.

RTI captures super high resolution analysis on every single frame, whereas other similar services only take one sample, the equivalent of a single pixel camera, scrambling the issue to the human eye. Furthermore, the machines that RTI have developed are also easy to use, only taking 60 seconds to get on track, calibrate and begin data collection. RTI uses one machine and one person, again separating itself as a more efficient source in the market.

GHH-BONATRANS designs, manufactures and supplies complete noise absorbing systems specifically aimed for different market segments of rail passenger transportation (urban, suburban and inter-city).

Safety assurance for onboard signalling and safety systems including ETCS and CBTC

Rail flaw detection

GHH-BONATRANS designs, manufactures and supplies complete noise absorbing systems specifically aimed for different market segments of rail passenger transportation (urban, suburban and inter-city).

RTI offers a full rounded ultrasonic rail testing service. Powered by their proprietary 8800SX technology, RTI offers a level of detectability and repeatability second to none.

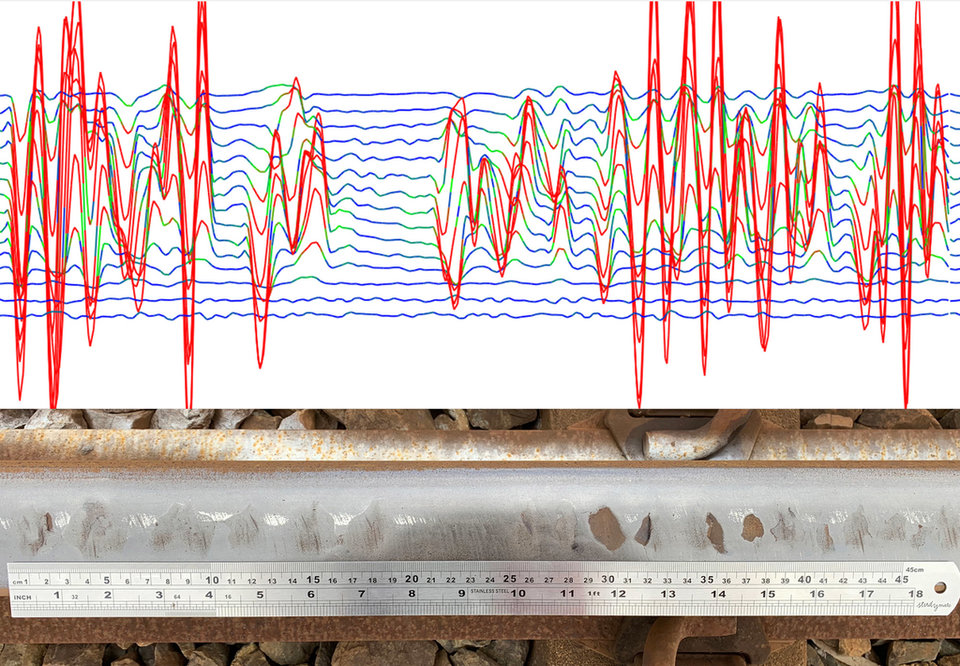

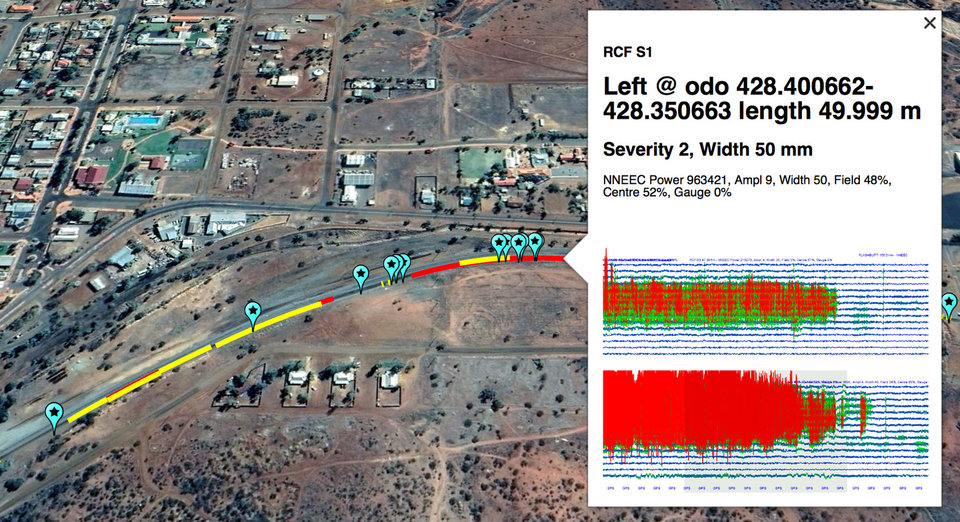

One of the key analysis tools that RTI has developed is SurfaceMap. This technology captures 30 high resolution digital magnetic signatures across the rail head, including the gauge corner, of each rail every 1mm of travel. Up to 20,000 samples per frame, per channel, per rail is recorded. SurfaceMap allows users to make informed maintenance decisions.

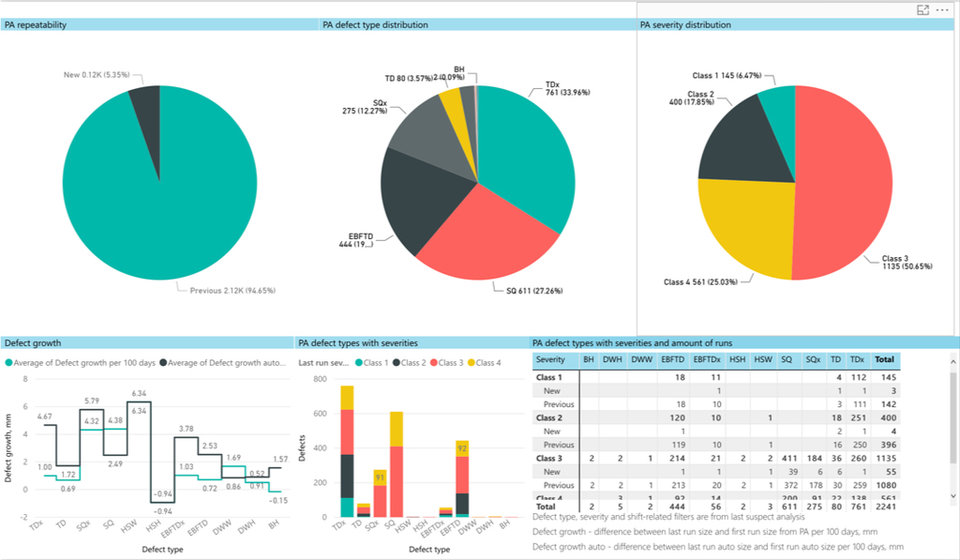

RTI knows that pinpointing the problem areas across rail networks is crucial, faults are detected earlier, ultimately reducing the cost of future maintenance and improving safety.

RTI SurfaceMap Technology detects:

- Rolling contact fatigue (RCF)

- Surface breaking transverse defects (TD)

- Defective welds

- Crack detection in switches and frogs

- Welds

- Rail ends

- Insulated rail joints (IRJ)

- Squats

- Engine burns

- Hunting

- Track pumping

- Low level corrugations

GHH-BONATRANS designs, manufactures and supplies complete noise absorbing systems specifically aimed for different market segments of rail passenger transportation (urban, suburban and inter-city).

Safety assurance for onboard signalling and safety systems including ETCS and CBTC

Safety assurance for onboard signalling and safety systems including ETCS and CBTC

Examination and exploration

When it comes to flaw detection, detailed analysis is crucial. RTI Analytics provides clients with in-depth knowledge about their rail systems, monitoring thousands of suspect defects and ultimately providing prevention for future maintenance. RTI Analytics can recover signals from noise, complete run to run history monitoring and using its smart technology, make sure maintenance is scheduled and not reactive. By using the RTI Analytics system clients are able to identify growth trends across their networks too, leading them into a stronger position for profit.

Taking on the world

RTI provides rail testing and condition monitoring services all around the world. With over 33 years of experience in ultrasonic rail flaw detection, the company is in a position to attend to all rail flaw and testing needs.

RTI works with clients in almost all continents on the globe, and has adapted its smart technology to fit the requirements of each country's regulations and government standards.

CEO and Founder of RTI Alex Ivachev says “When we first started out in the 1980’s, we knew that our approach to innovation was going to stand out but if I’m honest, I didn’t expect our developers to be producing such a diverse approach to detection in such a short period of time. From the first day we opened our doors we adopted a strict philosophy of constantly developing better technologies so we can ensure problems are found before they begin. Our team is focused on designing and developing systems that produce repeatability, repeatability and repeatability. It is not enough to simply find the flaws in rails, but to find the cause before they exist."

World leading technology and ongoing commitment to research and development is why RTI has played such a fundamental role in the rail testing industry over the last three decades.