Using lightbulbs in signaling systems

Artificial light sources have a long tradition in railway signaling. In parallel with the upcoming of electrical relay signal boxes in the 1930s, electric position light signals were introduced and are still in widespread use. This type of signals is equipped with electrically monitored and controlled light bulbs.

A light bulb is inexpensive and easy to monitor due to a quite definite correlation between lamp current consumption and brightness. However, a light bulb has a quite limited life span of 2000 operating hours, so that regular routine exchanges are necessary. This is not only time-consuming, but also exceeds the pure costs of spare light bulbs multiple times. Furthermore the light intensity is degrading and spontaneous fails may occur.

The solution: The “eternal light”

With the emergence of LEDs in the late 20th century, their advantages for the field of railway signaling became quickly evident: LEDs are utterly robust and became available in different colors and sizes. Soon the idea was born to replace conventional lamp signals by LED signals in already existing signaling systems. However, it was requested that these signaling systems must not needed to be modified and that their safety functions must not be impaired.

This was not too easy to accomplish, because light bulbs and LEDs encompass completely different features.

Replacing the light bulb – a true challenge

The correlation between current consumption and illumination allows a quite easy way of light bulb monitoring by current measuring during operation. Once the filament burnt through, the circuit is interrupted. Furthermore, some signaling installation types are enabled to reduce the supply voltage at night by approximately 20% which also decreases the signal current accordingly.

The commonly used light bulbs have a voltage of 12 or 24V. In order to achieve longer control distances of some kilometers to connected signals, higher voltages between 100 V and 200 V are required which need to be transformed down to the lamp voltage at the signal. When using AC voltage, line losses can be easily compensated by taps on the transformers.

LEDs, on the other hand, do not provide a clear connection between current flow and light emission. Electricity can also flow through defective LEDs. Reducing the voltage by 20% barely decreases the intensity of the LED. Because of their higher degree of efficiency, LEDs are consuming less energy than a light bulb at comparable light intensity.

Also to consider: A classic light bulb signal requires only one light element while LED signals consist of a matrix made up by many LEDs.

To solve the issues resulting from these differences between the illuminants used in signals, BBR has developed a universal electronic control system which enables displaying light aspects as well as variety of numbers and symbols for displaying additional signal aspects.

Beginnings at BBR: LED matrix signals for light rail trains

BBR Verkehrstechnik has discovered the advantages of LEDs very early. The development of LED-Signals has already been initiated when the company was founded in 1990. It all started with the development of single-aspect tram signals according to the German BOStrab regulations for building and operating light rail systems.

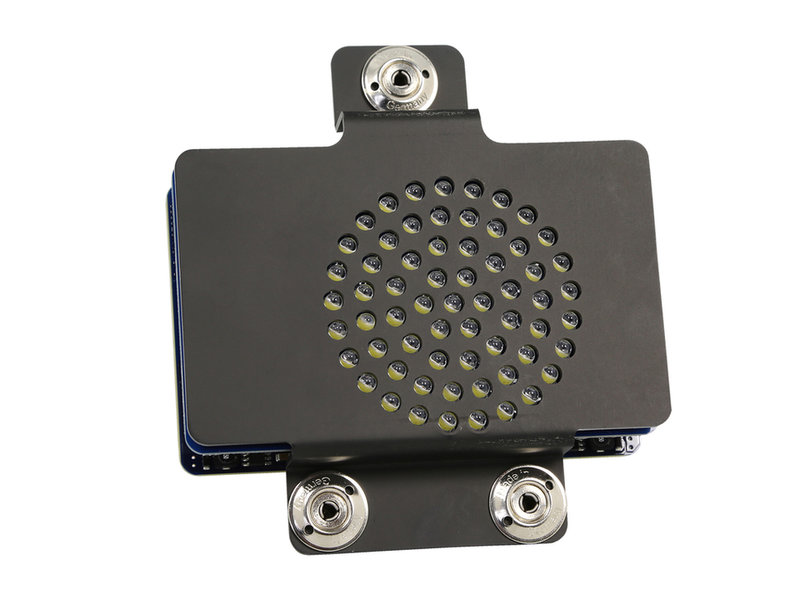

The signal aspects are formed by arranging LEDs on a board in a certain pattern. Every LED is a unique optical system. This technique is highly cost-effective and allows a wide range of different symbols depending on the clients’ needs.

Shortly after the development of tram signals had begun, BBR started to combine different symbols in one single signaling device. Every aspect could be switched individually. This approach reduced the costs remarkably. It made signals a lot easier to install and more cost-efficient. The development reached its climax in a combined signaling device which could alternatively display the aspects F0 (stop) and F1 (proceed) as well as the points position indicator aspects W1, W11, W2, W12, W3 and W13.

Another company’s milestone has been reached by the development of a universal LED matrix signaling device. It combines a double-digit 5x7-Matrix with a tram signal to display the destination track on marshalling yards or depots. Besides numbers, also letters or special characters can be displayed.

All tram signals are compatible with common housings for aspect diameters. Versions for 200 mm and 300 mm are available. The electrical interface to the signaling system is usually laid out for 40 V DC. This voltage is adjustable so that the cable resistance can be compensated.

The colorful world

BBR decided to expand their product range in order to produce signals according to EBO, the German regulation for heavy rail systems completely based on safe signalised operation. This regulation demands red, yellow and green signal aspects. In 2004, BBR introduced a series of 136 mm signal aspects which meet these requirements. They also come with a white marker light of 70 mm in diameter.

Meanwhile LED signals by BBR are also operating successfully in heavy rail networks, e.g. the City-Bahn at Chemnitz (Germany) and several mountain railways in Switzerland. Most of the European railway authorities have already approved their signal safety, others are currently preparing the approval.

At a glance:

- Developed according to CENELEC SIL4

- Safety-orientated switch-off in case of failure

- Adjustable day and night mode operation

- Supports flashing

- Widely maintenance-free throughout the system lifetime

- High availability

- MTBF above 1.000.000 hours

- Unlimited life span concerning safety

- Compatible with various interlocking systems

- Easy to install and to maintain

- Suitable as replacement for double-filament lamps

Contact Us

BBR Verkehrstechnik GmbH

Pillausstraße 1e

38126 Braunschweig

Tel.: +49.531.27300-0

info(at)bbr.net